Opportunities for olive oil value chain enhancement through the by-products valorisation

1. List of participants

| Participant No | Participant organisation name | Country |

|---|---|---|

| 1 Partner 1 (Coordinator) | University of Jaén (UJA) | Spain |

| 2 Partner 2 | Olive Tree Institute (IO) | Tunisia |

| 3 Partner 3 | Ankara University (AU) | Turkey |

| 4 Partner 4 | Olive Research Institute (ORI) | Turkey |

| 5 Partner 5 | Direction Générale de la Production Agricole (DGPA) | Tunisia |

2. Project summary

Olive oil value chain generates a variety of by-products, particularly during the agricultural and oil production phase, which currently are neglected and dealt with as a waste. This increases the costs for waste treatment of each olive mill, resulting in a heavier economic an environmental burden across the value chain. Moreover, during the agricultural phase many good agricultural practices should be monitored in order to minimize the environmental and economic impacts such as the choice of the cultivar, the density of plantation, the irrigation system adapted and fertilization operations, pruning, chemical pest control and harvesting among others. Thus, in order to design a more efficient and environmentally friendly olive oil chain, Life Cycle Assessment (LCA) is an important methodology to identify the processes which give the most significant environmental problems. The aim of the Project OLIVEN will be to define successful technologies for olive industry wastes and by-products valorisation focusing on the value chain enhancement for Spain, Tunisia and Turkey. To achieve this, several objectives will be carried out: a) to develop a state-of-the-art of the olive oil value chain and current by-products and wastes valorisation techniques in each country involved; b) to identify innovative and mature technologies for olive by-products and wastes valorisation; c) to perform a comparative LCA and Life Cycle Costing (LCC) of the current most representative olive oil value chains, evaluating the improvements proposed. Thus, the following expected results will be achieved:

- To provide useful information for local association of olive oil producers in Spain, Tunisia and Turkey in order to change their habits towards more sustainable solutions and to rethink the local value chain in a systematic way.

- To obtain new solutions and innovative techniques for by-products and wastes valorisation (based on successful technologies) for a better environmental and economic sustainability management of the olive oil value chain.

- To improve soil and water quality and agronomic practices with limited input use of energy, water and chemical products (pesticides and fertilizers).

- Enhance the farmers' and olive oil producers’ incomes through access to new markets as energy auto-production and exportation (thermal and electricity), biomass traders, biofuels and fertilizers production, boosting the rural economy.

3. Scientific quality of the project

Concept and objectives

- Relevance of the proposal to the topics addressed by the call:

Olive oil industry is one of the most important food industries in many EU and non-EU countries in the Mediterranean region and a form of production with numerous harmful effects on the environment. OLIVEN will address innovative technologies for the valorisation of wastes and by-products produced in the value chain of olive oil in order to boost rural economy as well as reduce the environmental footprint of this characteristic product of the Mediterranean area. Based on previous and ongoing research, the feasibility of applying technologies proven successfully in other sectors (at lab, semi-industrial or even industrial scales) will be carried out. Both the environmental and economic impacts of applying such technologies in the value chain of olive oil production will be estimated, taking into account the special features of the Spanish, Tunisian and Turkish markets.

- Background, “State of the Art” in the field and concept:

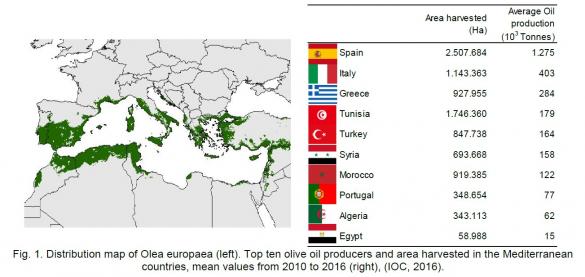

The cultivation of olive trees (Olea europaea L.), the production and use of olive oil have been a well-known and established practice in the Mediterranean countries for more than 7.000 years. The most dedicated area to this crop is concentrated in Spain, followed by Italy and Greece Fig. 1 (IOC, 2016). Olive oil sector is nowadays facing several stresses that push towards the need of a new approach, not only to cultivation, production, logistics and consumption but also to by-product and waste management and, in the final analysis, to enhance sustainability. Thereby, it is crucial to adopt a holistic vision to manage the olive oil sector as a whole, and here is where the value chain management plays a crucial role.

Thus, participating countries of the present research project proposal has been selected, considering the restrictions of the present call, to represent the largest possible worldwide production quota (average during the last six years: 55.1%). In Spain, the main producer worldwide, olive groves constitute the largest cultivated forest of Europe, with more than 180 million trees (more than 2.5 million ha), (IOC, 2016). In the past years the sector has experienced important investments in the modernization of the olive mills that resulted in many of the older, traditional mat presses being replaced by more modern, high volume continuous flow plants utilizing centrifugal separation (2 or 3 phases) of the oil from the rest of the olive fruit and thus leading to an improvement of the yield. The milling is usually structured in cooperatives result of the association of many producers. This influences the later treatment given to the residues, therefore large olive holdings are a very important part of the sector. Currently, there are around 1,743 operative olive mills, 72% are based on 2-phase extraction process, representing the main extraction system with more than 90% of total olive oil produced (Andalusian Energy Agency, 2016).

Tunisia currently has 82.425 million olive trees covering 1,835,000 ha, which represents a third of the nationally available agricultural land (DGPA, 2015). In Tunisia there are more than 1,700 oil mills with triturating capacity of 44,077 tons per day (ONH, 2016). The processing sector is going through a transitional stage featuring the creation and modernization of olive oil mills and the gradual move away from traditional methods. Three extraction systems currently coexist, namely the traditional oil mills, the super pressing system and the most dominant continuous system (2 or 3-phase), accounting for 65% of the total triturating capacity.

In Turkey, 846,000 ha of land are dedicated to olive production. As of 2015/2016 season, 73% of total olives produced in Turkey have been used for olive oil production. The olive producers are mostly small-scale and family enterprises and the number of estimated olive mill is around 1187 with an average 858.000 t of yearly production capacity and 280.000 t of production, which implies an excess capacity of 75% (ZAE, 2016). In the olive processing stage, around 56% of olive oil mills are using 3 phase processing system, 35% are using 2-phase and the rest is mixed (ZAE, 2016). Moreover, there are 15 olive oil refineries and 20 pomace extraction plants, of which 14 use traditional methods and 6 use the centrifuge technique (ABGS, 2006).

Olive oil industry wastes

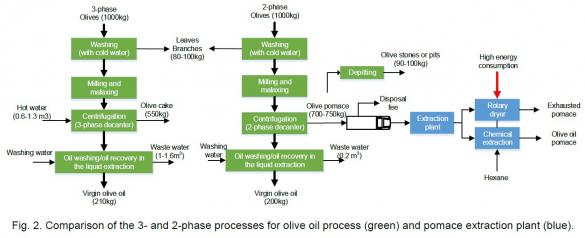

The olive oil value chain generates variety of by-products and wastes, particularly during the agricultural phase (harvesting tasks) and oil production, such as olive pruning residues, olive stones, pomace, olive mill waste water and leaves and branches (García-Maraver et al., 2012). The amount and physico-chemical properties of the wastes produced depend on the olive oil extraction method. Taking into account the more extended and high efficiency oil extraction processes (continuous 3 and 2-phases) the wastes generated at the mill are presented in Fig. 2.

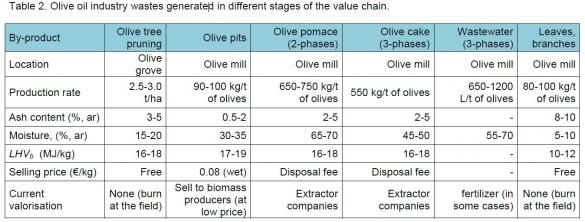

One of the most abundant wastes of the olive oil value chain is the punning of the olive trees. It is estimated that one hectare of olive grove produces 2-3 tons of pruning´s per year (Vera et al., 2014). Two main different applications for this pruned biomass are predominantly used: either it is ground and scattered in the field as mulch, or by burned at the field, which is a source of environmental concerns, as well as a waste of a resource (Romero-García et al., 2014). Currently, a small amount of this residue is used for pellet production, however, there are several studies which indicate this feedstock might cause several combustion problems as a consequence of their ash content (around 5-6% by weight) (García-Maraver et al., 2014).

Olive leaves and small twigs are also considered a waste of the olive oil industry. According to Malheiro et al. (2013), this residue can reach 8-10% of the total weight of processed olives. Nowadays, their separation, storage and elimination entail an increasing cost for the mill owners (de Mena et al., 2017). Table 2 summarizes the rate of production, cost and main properties of the wastes generated during

the main phases of the olive oil value chain (Malheiro et al., 2013; Pesta and Mayer Pittroff, 2007; Vera et al., 2014).

There are numerous projects and works focused on the successfully valorisation of olive industry wastes, highlighting the project RESOLIVE (RESOLIVE, 2010). As an example, olive pruning, leaves and small branches are suitable fuels for energy production (electricity and heat) through consolidated technologies as combustion and gasification applied for microturbines, gas engines and organic Rankine cycles. This way of valorisation could be a good option for improving the olive oil value chain by the access of new incomes as the renewable energy production (and exportation) and the reduction of losses and wastes along the chain. Moreover, exhaust gases from biomass power plants can be used in rotary dryers to produce exhausted pomace and increase the energy value of the olive pits (access to biomass traders). Olive pomace and cake can be directly dried in solar devices (Industrie- & Trocknungstechnik, 2017; Maragkaki et al., 2016). Also, Malheiro et al. (2013) and Sevim et al. (2013) have demonstrated the potential antioxidant capability of the olive leaves, increasing the value added of the virgin olive oil.

LCA in olive oil value chains

The olive oil value chain can be briefly described as follows (EMAF Project, 2010; LIFE, 2017; OILCA, 2012), using the different life cycle phases of the olive oil product: cultivation, olive oil production, by-product management, product transportation and distribution, consumption and waste management.

LCA is an important approach to identify the processes which give the most significant environmental and economic problems, serving to design a more efficient and environmentally friendly olive oil chain. In the last ten years (from 2008 to 2017), some studies are focused on LCA applied to the olive oil industry, (Salomone and Ioppolo, 2012) performed a LCA in the province of Messina (Italy) for nine different scenarios along the three main phases of the olive oil supply chain: agricultural, oil production and waste mill treatment. Significant contributions were obtained as high environmental load associated with fertilization sub-process, use of pesticides and combustion of exhausted pomace. Also, positive environmental enhancement was associated with the use of by-products as fuel, fertilizers, cosmetics, and pharmaceuticals. In the same line, a life cycle inventory case study in Cyprus was studied by Avraamides and Fatta (2008). Tsarouhas et al. (2015) presented a case study of olive oil production in Greece; LCA was applied taken into account fourteen sub-systems of the overall value chain providing useful managerial insights and diagnoses the relevant environmental “hotspots”. Olive harvesting and oil production sub-processes represented the most important environmental harmful phases. Romero-Gámez et al. (2017) carried out a comparative analysis of the environmental impacts of a high diversity of olive growing systems existing in Spain taking into account eight traditional systems, three intensive and one super-intensive system. According to the Authors, optimization of fertilization should be the first priority to optimize olive growing, moreover, intensive and super-intensive irrigated integrated systems presented the largest environmental impact for most categories studied. In the same line, De Gennaro et al. (2012) performed an environmental and economic assessment of two olive-growing systems: the “High Density” and the “Super High Density”. Rinaldi et al. (2014) calculated the “cradle-to-grave” carbon footprint and energy footprint of extra virgin olive oil produced in the province of Perugia (Italy). The most harmful process was the distribution followed by olive orchard fertilization, oil freezing and manufacture of glass bottles. El Hanandeh and Gharaibeh (2016) presented an environmental efficiency of the small and micro-scale olive oil production sector in northern Jordan using LCA. The results showed that dry organic farming practices are dominant in the region showing low use of chemical fertilizers, chemicals pesticides and herbicides, low mechanization, bulk packaging and efficient use of waste material. On the other hand, it is important to highlight the energy-economic LCA of Rajaeifar et al., (2014), these authors calculated the energy consumption, economic flows and GHG emissions in the olive oil sector in Iran. Agricultural olive production stage ranked the first in energy consumption and GHG emissions followed by olive oil extraction stage. Finally, concerning waste management of the oil sector, El Hanandeh (2015) studied a LCA methodology to compare five alternatives for wastes valorisation from 2 and 3-phases oil processes in Australia: wastewater, olive pomace and cake. The results showed that manufacture pellets for domestic water heating was the highest environmental benefits followed by briquette manufacturing for use in domestic stoves for space heating.

In conclusion, although a number of relevant papers and researching projects studied the LCA in different phases/stages and echelons/levels of the olive oil value chain, most of them are focused on the development of the environmental profile of actual olive oil production or agricultural harvesting. Moreover, there is there is a lack of studies and projects focused on the impact assessment in the current wastes valorisation techniques. Thus, the project OLIVEN will identify the opportunities for olive oil value chain enhancement through the by-products valorisation.

- Aim, objectives and hypotheses

The main aim of the Project OLIVEN is to define successful technologies for olive industry wastes and by-products valorisation focusing on the value chain enhancement for Spain, Tunisia and Turkey. To achieve this aim, several objectives will be carried out:

a) To develop the State-of-the-art of the olive oil value chain and current by-products and wastes valorisation techniques in each country involved.

b) To identify innovative and mature technologies for olive by-products and wastes valorisation.

c) To perform a Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) of the current most representative olive oil value chain from “cradle-to-gate”.

d) To carry out a comparative LCA and LCC analysis to evaluate the improvements proposed trough future simulated scenarios.

Finally, it is important to highlight the OLIVEN project objectives meet really well with the following Horizon 2020 social challenges: 2nd. Food security, sustainable agriculture and forestry, marine and maritime and inland water research, and the Bioeconomy; and 3rd. Secure, clean and efficient energy.